Clean-tech startup company Form Energy announced last week an additional $405 million in financing, allowing it to expand its newly built factory where it makes a unique type of large-scale battery for long-term energy storage on the electric grid.

“This technology, iron air, is low cost enough that you can discharge for 100 hours,” Form Energy CEO and co-founder Mateo Jaramillo told Newsweek. “That’s the duration that we need to be able to really drive increased reliability in the electric system.”

Energy storage has become one of the biggest recent developments in the country’s electric grid system. Banks of massive batteries allow grid operators to better manage many of the challenges of meeting peak times of demand for electricity and integrating intermittent power from renewable sources such as wind and solar.

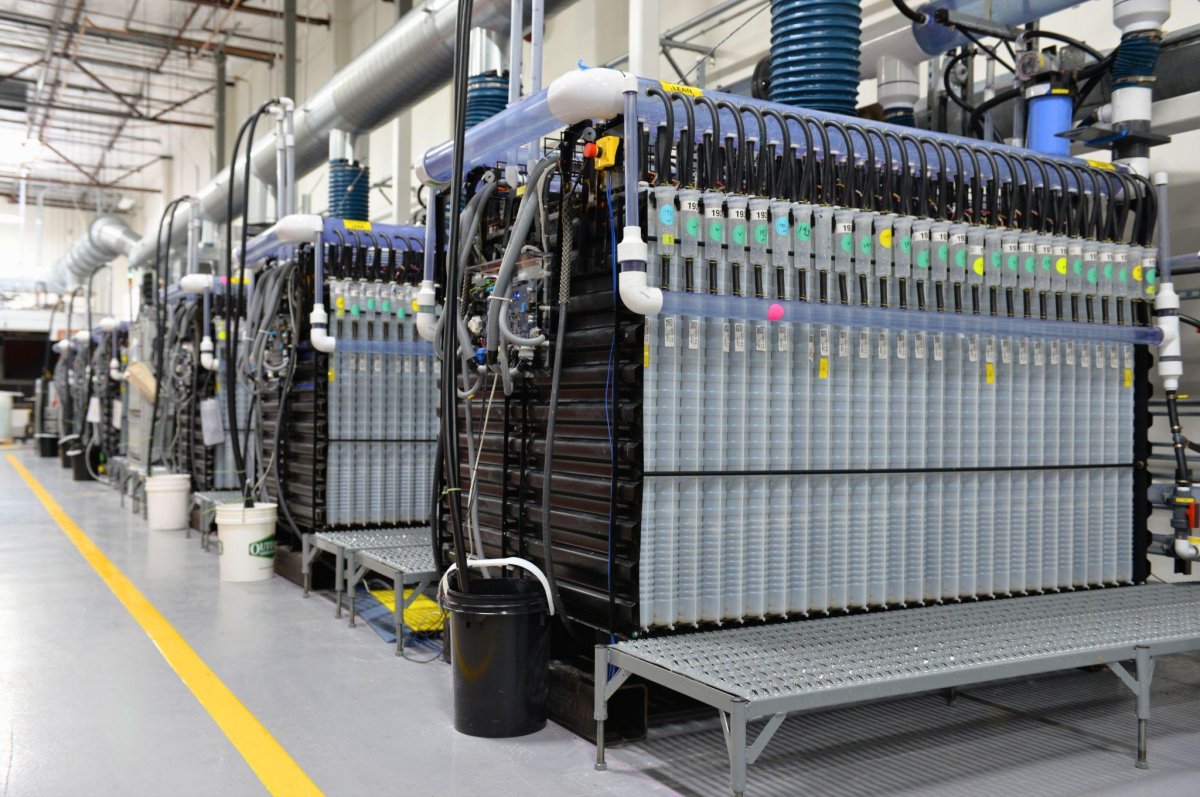

Courtesy of Form Energy

Most of the current large-scale batteries rely on lithium-ion technology, as found in an electric vehicle or many home electronics. Lithium-based batteries are fast-charging and lightweight, great for an EV but not characteristics that matter so much for the task of grid-scale energy storage.

Form’s batteries use a much simpler—and cheaper—technology. The batteries use iron, air and the rusting process to store and release energy.

“When a building rusts or a bridge rusts, it is very slowly discharging [energy],” Jaramillo explained. Form’s batteries can reverse the rusting process with the addition of electric current, turning rust back to iron and releasing oxygen. When the energy is needed, the battery takes in oxygen, rusting the iron and releasing some energy.

“What we have done is build a device that takes that reaction and harnesses it and lets us manufacture that battery and deploy it in very large volumes,” he said.

Courtesy of Form Energy

The iron-air energy storage system is less efficient than other battery technologies, but Jaramillo said that the lower cost and longer duration of storage more than compensate for that. While the energy storage for lithium-ion batteries is measured in hours, the iron-air battery duration is measured in days. That gives electric utility companies and grid managers far more flexibility in how they dispatch power.

“It allows them to have an electric system that lasts longer than the weather,” Jaramillo said.

The U.S. electric grid is under tremendous strain from the combination of growing demand, aging infrastructure and the increased risk of disruption from extreme weather. At the same time, many electric companies are working to decarbonize their power generation by retiring old fossil fuel burners and adding clean renewable energy. That presents its own challenges because wind and solar energy are only available at certain times of day.

Grid-scale storage has become an attractive way to address many of those issues by “banking” cheap electricity for later use and providing a backup source of power during times of very high energy demand or disruption from storms.

A recent report from energy analytics company Wood Mackenzie and the energy industry trade group American Clean Power Association measured the remarkable recent growth in grid-scale storage.

In 2024, the report said, the U.S. is on track to deploy about 12.7 gigawatts of storage capacity. For context, a gigawatt is enough energy to power about 750,000 average homes.

That level of growth holds the promise to help transform the nation’s power grid. Similarly, Form Energy’s growth is helping to transform the company’s host community, Weirton, West Virginia.

The latest round of fundraising brings Form’s total financing to more than $1 billion. The company is expanding its manufacturing operations just a little more than a year after breaking ground on an old industrial site with major historical significance for Weirton, the former Weirton Steel mill.

Courtesy of Form Energy

Weirton was named for Ernest Weir, the steel industry pioneer who selected the site along the Ohio River in West Virginia’s northern panhandle more than a century ago. At one point, Weirton Steel was the state’s largest private employer and was part of the thriving steel operations along the Upper Ohio Valley that helped build much of modern America.

When the U.S. steel industry contracted due to foreign competition, the steel mill eventually closed and Weirton suffered the fate of many Rust Belt towns with sharp declines in population, tax revenue and jobs.

Jaramillo said that when Form Energy was considering a manufacturing site, Weirton stood out for its available land near a rail line and river, and the state offered an economic incentive package worth $290 million to support redevelopment of the site. Form has also enjoyed support from the federal Bipartisan Infrastructure Act, which provided a $150 million grant, and the Inflation Reduction Act supports some of the energy projects that will include Form Energy batteries.

With the expansion of the factory, Jaramillo said, Form aims to generate 750 jobs by the end of 2028.

“We feel like we have hope again, and it’s been quite a lift, both emotionally and psychologically,” Weirton City Manager Mike Adams told Newsweek.

Adams said Form Energy has been a good partner living up to its commitments so far and has also worked to recognize the steelmaking heritage of the city and the factory site. Historic photographs and artifacts from the steel mill line the lobby in the Form Energy factory, he said, and Adams finds it fitting that the city once again has a manufacturing base that uses iron.

“If we can take a process that uses our main product and turns it into stored energy, it’s really kind of cool,” Adams said. “We’re in the reverse rusting business now.”